Galla Foods plant is equipped to process fruit pulps & concentrates with Aseptic Packaging facility.

Galla Food’s technology initiatives span the following disciplines:

- PLC operated equipment for better control over monitoring and operations with supervisory units.

- Two stage washing of fruits to ensure HACCP quality requirement.

- Two-stage sterilization to retain the natural flavor and aroma.

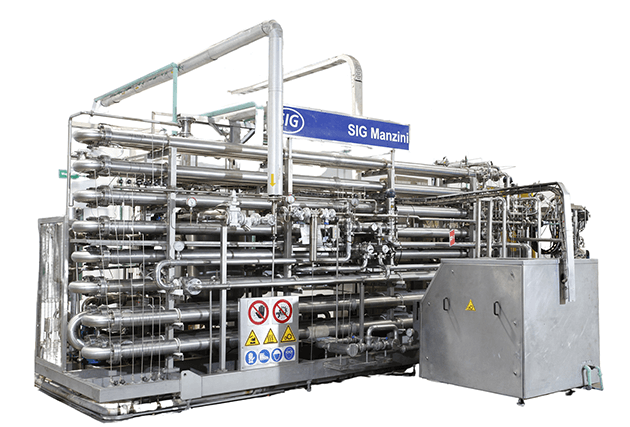

- High speed advanced Mono block aseptic filling machine supplied by SIG Manzini.

- Integrated Enterprise Resources Planning system is in place to automate business processes and provide data for analysis and reporting, allowing a closer control on quality and operations.

Efficient Plant Layout

- Minimal drop in power and steam transfer.

- Straight-line process flow design to maintain the hygiene and control in respective areas.

- Special food grade self-leveling epoxy flooring to maintain optimum hygienic conditions.

- Curved corners and food grade epoxy painted walls to avoid dust accumulation and to facilitate easy washing.

- Advanced high raise insulated roofing with double layer GI Sheeting with air extractors to maintain temperature inside the plant.

- Utility lines are routed outside the plant to keep the interiors free from dust accumulation.

Valuable Industrial Expertise

Galla Foods is backed with strong support and service from its team of highly qualified technical personnel and domain experts with perceptive knowledge and skill. Powered by priceless hands-on experience, these professionals keep upgrading themselves continuously to identify and introduce improved and innovative product offerings that would delight customers worldwide and comply with leading global quality standards.